Contact:Diane

Tel:+86 15837203567

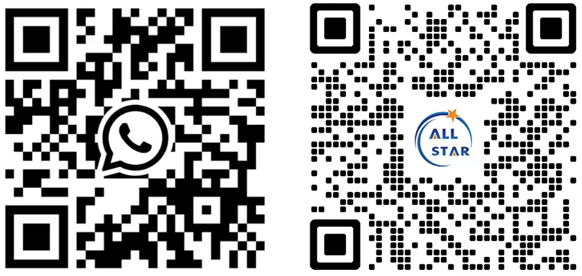

Whatsapp/Wechat:+86 15837248880 15837203567

Email:info@qxferroalloy.com

Website:www.a-star-alloy.com

Factory Add:Xiqugou,Qugou Town,Anyang,Henan,China

Office Add:17th Floor,Guomao Building B,Wenfeng District, Anyang,Henan,China

Silicon Barium(SiBa)

Details:

Silicon barium alloy (Si Ba)is a high quality inoculant. It is an iron alloy with higher activity. Silicon barium Inoculants apply to grey cast iron , nodular cast iron, ductile casting iron and vermicular casting iron.

|

Type |

Si |

Al |

Ba |

Ca |

C |

S |

P |

|

Si-Ba |

55-65% |

3% |

2-28% |

~ |

0.2-0.3% |

0.04% |

0.04% |

Size: 0.2-0.6mm, 0.3-1mm, 1-3mm, 3-8mm

Packing: 25kg woven plastic bag in 1mt jumbo bag.

一、What is silicon barium?

Silicon barium inoculant is a block shaped metallurgical material made by blending silicon powder and barium powder according to the required ratio, and then refining steel in a high-temperature furnace. It is an additive used in the casting process of a foundry, which can promote graphitization, reduce the tendency of white spots, improve the morphology and distribution of graphite, increase the number of eutectic clusters, and refine the matrix structure. It has good effects in a short period of time (about 5-8 minutes) after incubation treatment.

二、Specification parameters

Silicon: ≥ 65% Barium: 2.0-6.0% Calcium: 1.0-2.0% Aluminum: 1.0-2.0%

三、What is the function of silicon barium?

1.Strongly increasing the graphitization core, refining graphite, promoting the formation of A-type graphite in gray cast iron, improving strength. For ductile iron castings, it can make the graphite small, round, and improve the spheroidization level.

2.It can reduce the undercooling of molten iron, promote the precipitation of graphite, significantly reduce the tendency of white spots, lower relative hardness, and improve the cutting performance of castings.

3.Strong resistance to decay, with a decay time twice that of 75 silicon. The amount of silicon barium inoculant added is even lower than half of that of 75 silicon iron inoculant, while preventing associated spheroidization decay.

4.Low sensitivity to wall thickness, improving cross-sectional uniformity and reducing tendency for shrinkage and loosening.

5.Stable chemical composition, uniform processing particle size, and small deviation in composition and quality.

6.Low melting point (below 1300 °), easy to absorb during incubation treatment, with very little floating slag

四、What is the price related to?

The price of silicon barium alloy is influenced by various factors. The supply and demand relationship of raw materials plays a decisive role in prices. If the supply of raw materials for producing silicon barium alloys is scarce, prices will rise; On the contrary, if there is sufficient supply, the price will be relatively stable. Secondly, changes in market demand can also affect prices. If the demand for related industries increases, the price of silicon barium alloy may rise; On the contrary, a decrease in demand may lead to a decrease in prices. In addition, factors such as government policies, production costs, and market fluctuations can also have an impact on the price of silicon barium alloys.

五、What is the packaging method?

1.Generally, it is packaged separately in a 25kg small bag, and then packaged in a ton bag outside

2.We adhere to the principle of honest operation, establish long-term cooperative relationships with customers, and grow together. In future cooperation, we will continue to improve and innovate to provide you with high-quality products and services. We look forward to working with you. If you have any questions or needs about our products and services, please feel free to contact us at any time. I hope our cooperation can bring more benefits to both parties and achieve mutual benefit and win-win.

Related products

More>>ONLINE MESSAGE

Our professional team will reply to you within one business day. Please feel FREE to contact us!