Contact:Diane

Tel:+86 15837203567

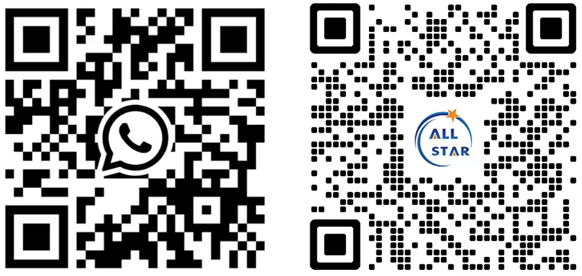

Whatsapp/Wechat:+86 15837248880 15837203567

Email:info@qxferroalloy.com

Website:www.a-star-alloy.com

Factory Add:Xiqugou,Qugou Town,Anyang,Henan,China

Office Add:17th Floor,Guomao Building B,Wenfeng District, Anyang,Henan,China

Mixed Refining Slag

Details:

1. The composition of premelted refining slag is uniform. It has better fluidity and has excellent comprehensive metallurgical effects, such as deoxidation, desulfurization and adsorption of impurities.

2. The pre-melting refining slag has a low melting point and a fast melting speed, which shortens the refining time, thereby shortening the entire time of steelmaking. It also improves the quality of molten steel and reduces slag consumption. At the same time, electricity consumption in steelmaking and the consumption of ladle refractories have also been reduced.

3. The advanced melting process makes the components of the refining slag to form a homogeneous compound, which makes it have strong component homogeneity and stable use performance.The uniform refining slag does not absorb moisture, which is convenient for storage and long-distance transportation.

4. After the pre-melting treatment, the refining slag can be broken into a certain particle size as required. This makes it difficult to generate dust during use and transportation, which greatly improves the production environment of the refining workshop.

The use of premelted refining slag can better improve product quality and save energy costs.

|

ITEM % |

55# |

50# |

35# |

|

CaO |

55 |

50 |

35 |

|

Al2O3 |

30 |

35 |

42 |

|

SiO2 |

4 |

5 |

5 |

|

Fe2O3 |

1 |

1.3max |

2 |

|

MgO |

5 |

5 |

5 |

|

C |

0.5 |

0.5 |

0.5 |

|

S |

0.05 |

0.1 |

0.1 |

|

TiO2 |

0.05 |

0.5 |

0.5 |

Related products

More>>ONLINE MESSAGE

Our professional team will reply to you within one business day. Please feel FREE to contact us!